- +86-18589219627

- shirley@litoscreen.com

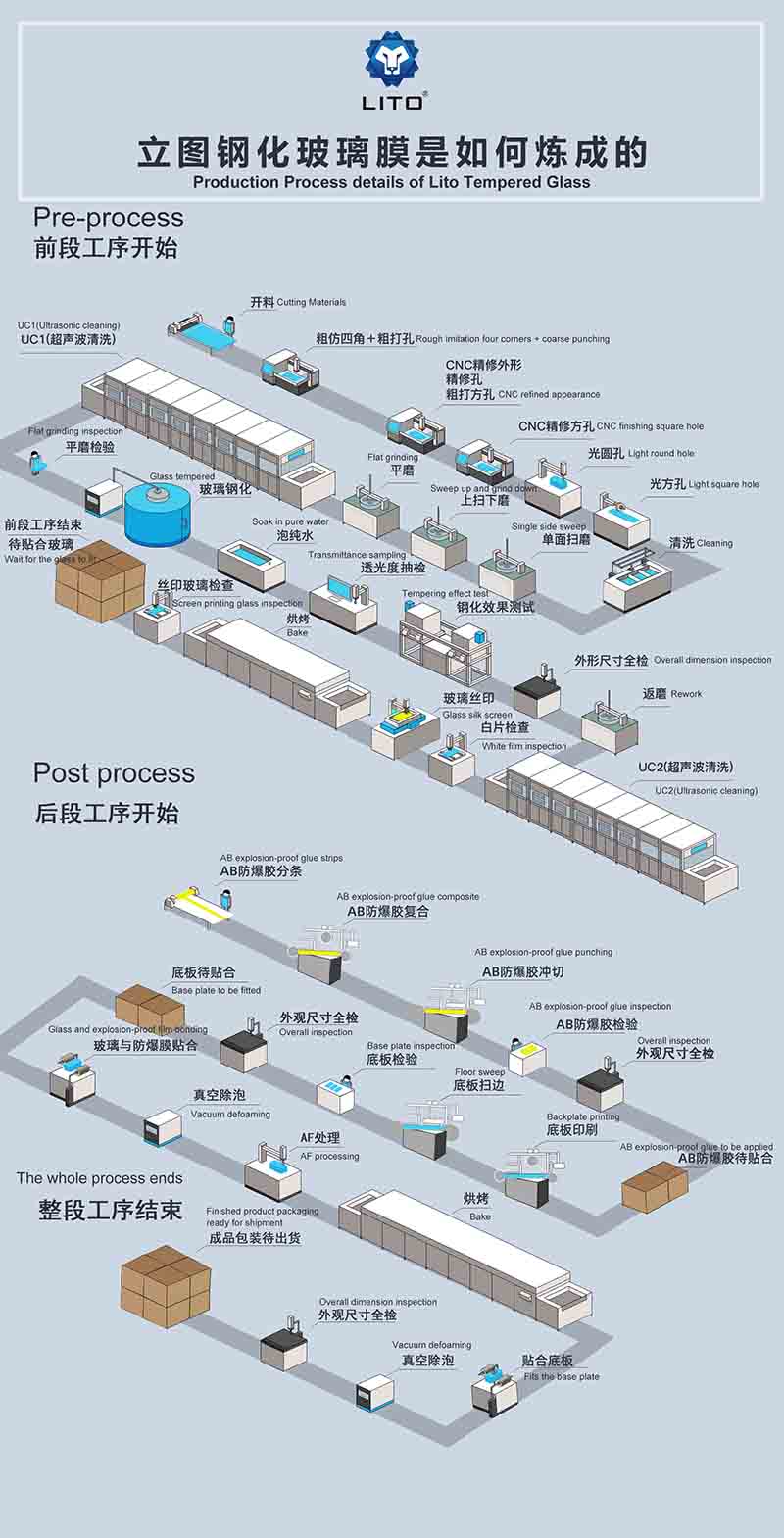

Crafting Excellence: The Journey of LITO Tempered Glass Screen Protectors

At Guangzhou LITO Technology, our pursuit of perfection is evident in every meticulous step of crafting high-quality tempered glass screen protectors for your smart devices. From raw material cutting to the final product packaging, each stage reflects our unwavering commitment to quality and precision.

Preprocessing - Setting the Foundation:

1.Material Cutting: We start with carefully selected high-quality raw materials, precisely cut for consistency.

2.Rough Imitation of Corners + Preliminary Drilling: Initial shaping and drilling lay the groundwork for the glass protector.

3.CNC Refined Appearance: Utilizing CNC technology for precise refinement of the protector's appearance.

4.CNC Finishing of Square Holes: Achieving perfection with precision machining of square openings.

5.Light Round Holes & Light Square Holes: Providing tailored round and square hole processing as needed.

6.Cleaning: Deep cleaning ensures optimal surface preparation for subsequent processes.

7.Single-Side Grinding: Carefully sanding to achieve smoothness and uniformity on one side.

8.Both-Side Grinding: Fully polishing to ensure smooth surfaces on both sides.

9.Flat Grinding & Inspection: Further refining flatness and inspecting for quality.

10.Glass Tempering: Enhancing product strength through the tempering process.

11.Soaking in Pure Water: Preparing the glass protector for subsequent treatment.

12.Transmittance Testing & Tempering Effect Evaluation: Checking light transmittance and tempering effectiveness for quality assurance.

13.Overall Dimension Inspection: Thoroughly inspecting the protector's dimensions for precision.

14.Rework & Ultrasonic Cleaning: Addressing any imperfections through rework and ultrasonic cleaning.

15.White Film Inspection & Screen Printing: Ensuring quality through white film inspection and precise screen printing.

16.Baking & Screen Printing Inspection: Curing prints through baking and inspecting screen quality.

Back-End Process - Achieving Perfection:

1.AB Glue Composite Stripping: Processing the adhesive for the protector.

2.AB Glue Punching: Precision punching of the adhesive.

3.AB Glue Inspection: Conducting rigorous inspections to uphold adhesive quality.

4.Overall Inspection & Base Plate Printing: Comprehensive inspections and printing for the base plate.

5.Base Plate Edge Cleaning & Inspection: Ensuring cleanliness and quality of the base plate.

6.Glass and Protector Bonding: Expertly bonding glass and the protective film.

7.Vacuum Defoaming & Anti-Fingerprint Coating: Using vacuum to remove air bubbles and applying anti-fingerprint coating.

8.Final Baking & Dimension Inspection: Curing coatings through baking and conducting a final inspection of product dimensions.

9.Product Packaging for Shipment: Packing finished products securely for shipping.

Conclusion:

From start to finish, our meticulous production process ensures the highest quality tempered glass screen protectors.

Choose Guangzhou LITO Technology for excellence in tempered glass screen protector production. Let us protect your smart devices and enhance your visual experience with clarity and safety.

To learn more or collaborate with us, please contact Guangzhou LITO Technology Company Ltd. Choose LITO, choose exceptional quality.

Categories

Copyright © 2015-2026 Guangzhou Lito Technology Co., Ltd..All Rights Reserved.dyyseo.com

Online Service

+86-18589219627